Skill Builder: VectorWorks, MasterCAM, and Techno CNC

Inspiration

I’ve been wanting to build a prize wheel for some upcoming events, e.g. my best friends wedding or next family gathering. But also as a meditation on gambling, change and joy. I found this great wikihow that details how to do it with a lazy susan. I’ve been modeling parts of my last couple of Subtraction assignments loosely based on this guide.

Old, Raw Materials

I had some off cut scrap wood from a past CNC project. (I’ve used the CNC before.) I figured I could cut a smaller circle out of the larger offcut.

Slightly offcut circle scrap plywood.

Slightly offcut circle scrap plywood.

Measuring the biggest circle I can make from the offcut.

Measuring the biggest circle I can make from the offcut.

The precut centerhole poses an interesting problem, how do I subtract a smaller circle from the offcut without having to precisely measure my origin!

The precut centerhole poses an interesting problem, how do I subtract a smaller circle from the offcut without having to precisely measure my origin!

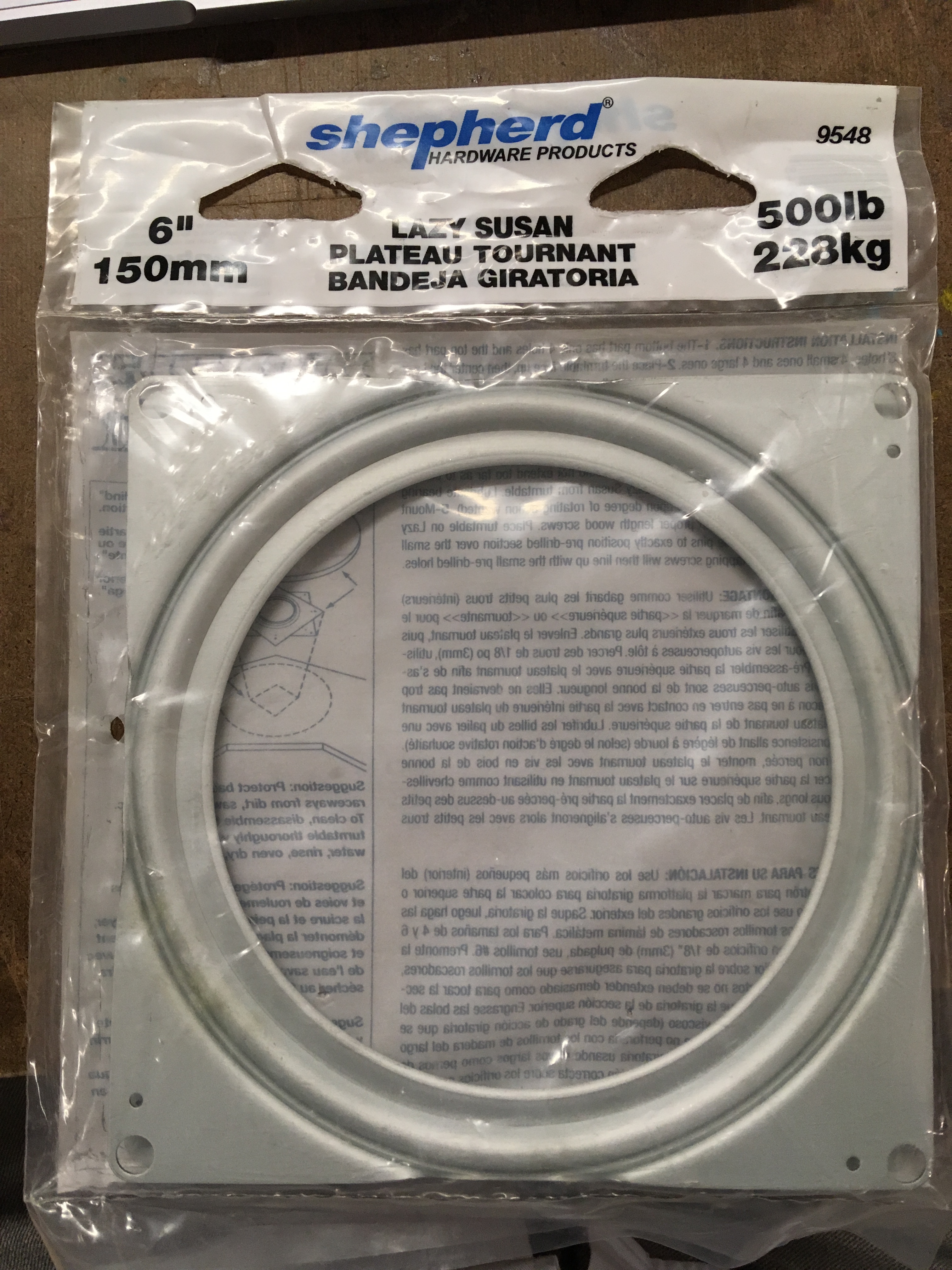

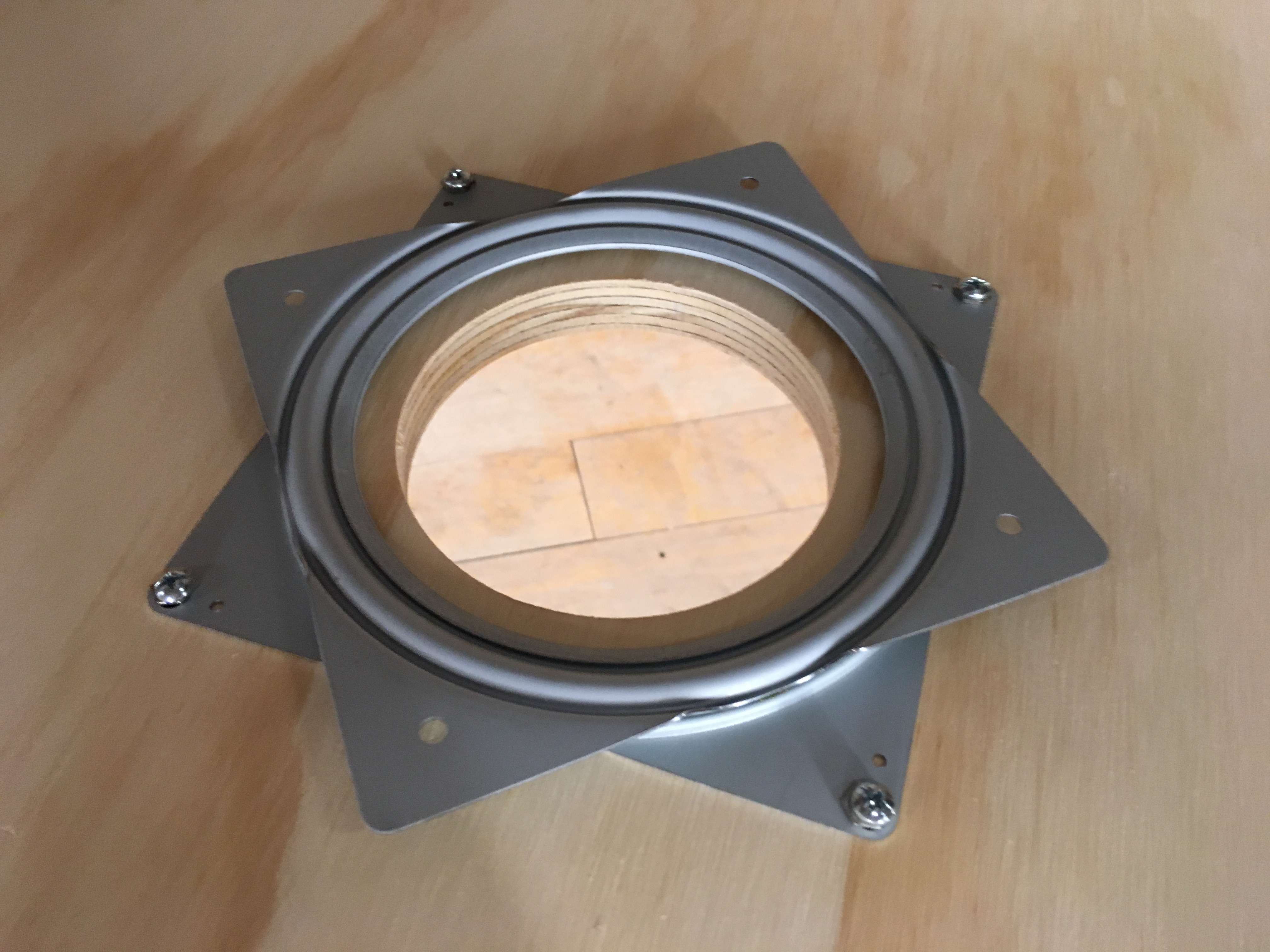

I bought a lazy susan for $7 at Ace Hardware nearby. The mounting instructions are quite intricate… and I wish it came with screws but I get why that is difficult…

I bought a lazy susan for $7 at Ace Hardware nearby. The mounting instructions are quite intricate… and I wish it came with screws but I get why that is difficult…

And some dowel pins to use as prize wheel pins because ITP students don’t know how to use nails… jk.

And some dowel pins to use as prize wheel pins because ITP students don’t know how to use nails… jk.

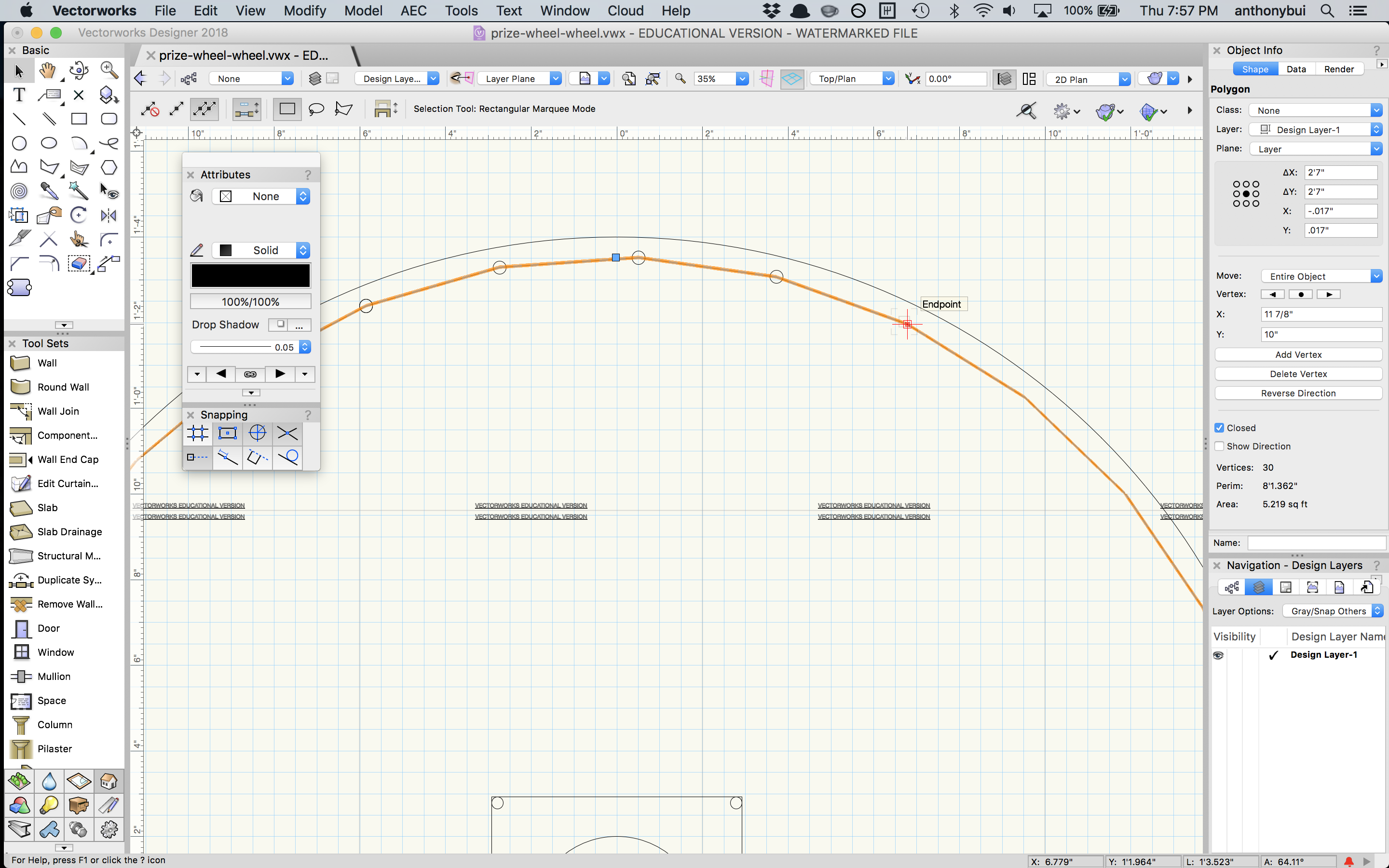

Falling in Love with Vectorworks

I had a rough time learning Vectorworks in a hurry last week. Because I’ve CNC’d before, I had some extra time to properly experiment with Vectorworks. Shortly put, it’s drag-drop snap alignment and paint bucket are absolute AMAZNG. I particularly loved that I could drag a part of one shape – e.g. center or right-most point of a circle – and it would snap my chosen point to another shape.

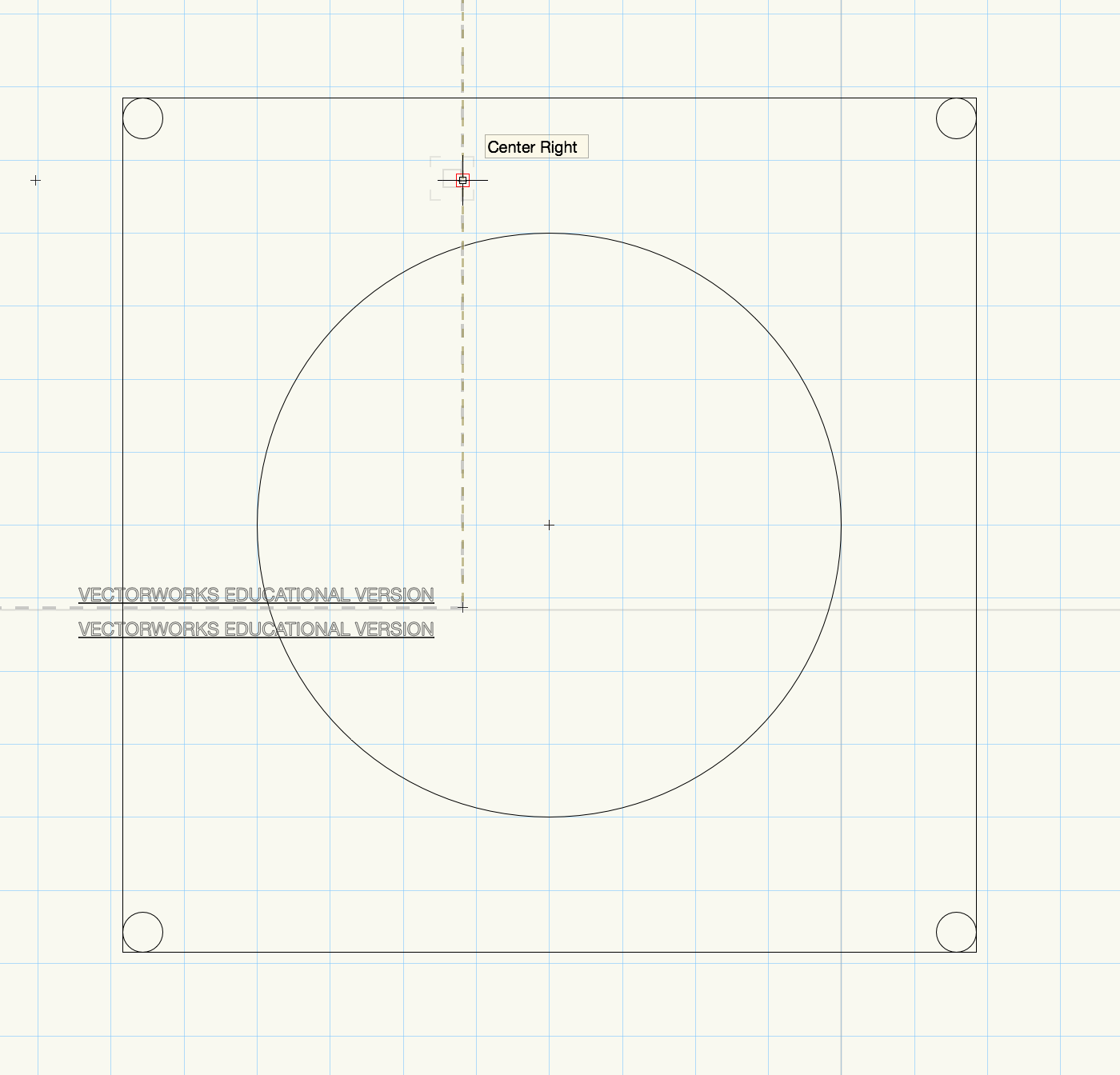

I measured out the lazy susan so I wouldn’t have to drill. A little nervous about the precision of the screw holes as I’ve measured and failed before (not on CNC).

I measured out the lazy susan so I wouldn’t have to drill. A little nervous about the precision of the screw holes as I’ve measured and failed before (not on CNC).

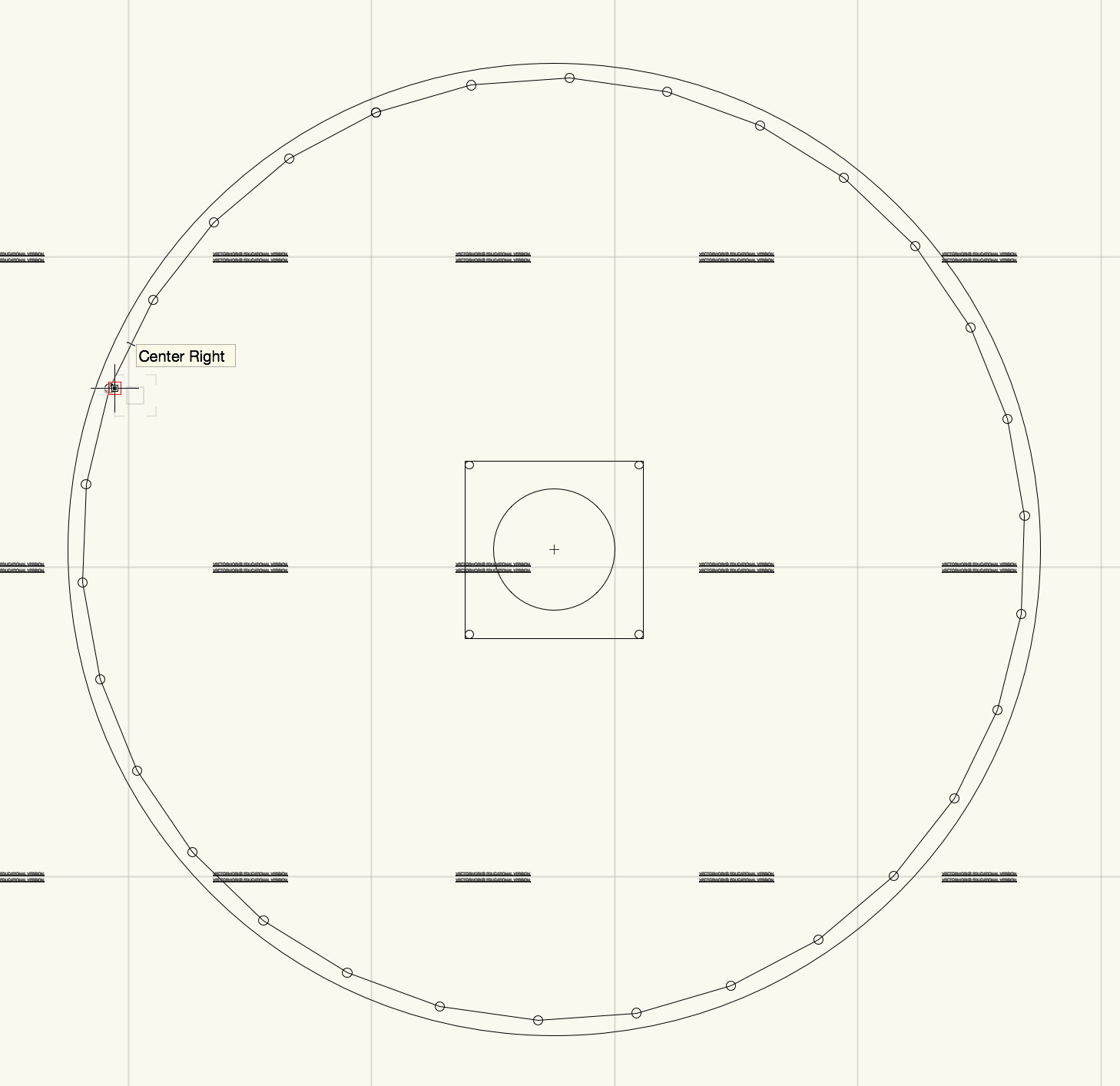

I add the outer wheel. Using a 30-sided polygon slightly smaller than my outermost circle, I align ~5/16” circles on my polygon vertices. So much easier than any other way I would’ve done it. <3

I add the outer wheel. Using a 30-sided polygon slightly smaller than my outermost circle, I align ~5/16” circles on my polygon vertices. So much easier than any other way I would’ve done it. <3

Overview shot

Overview shot

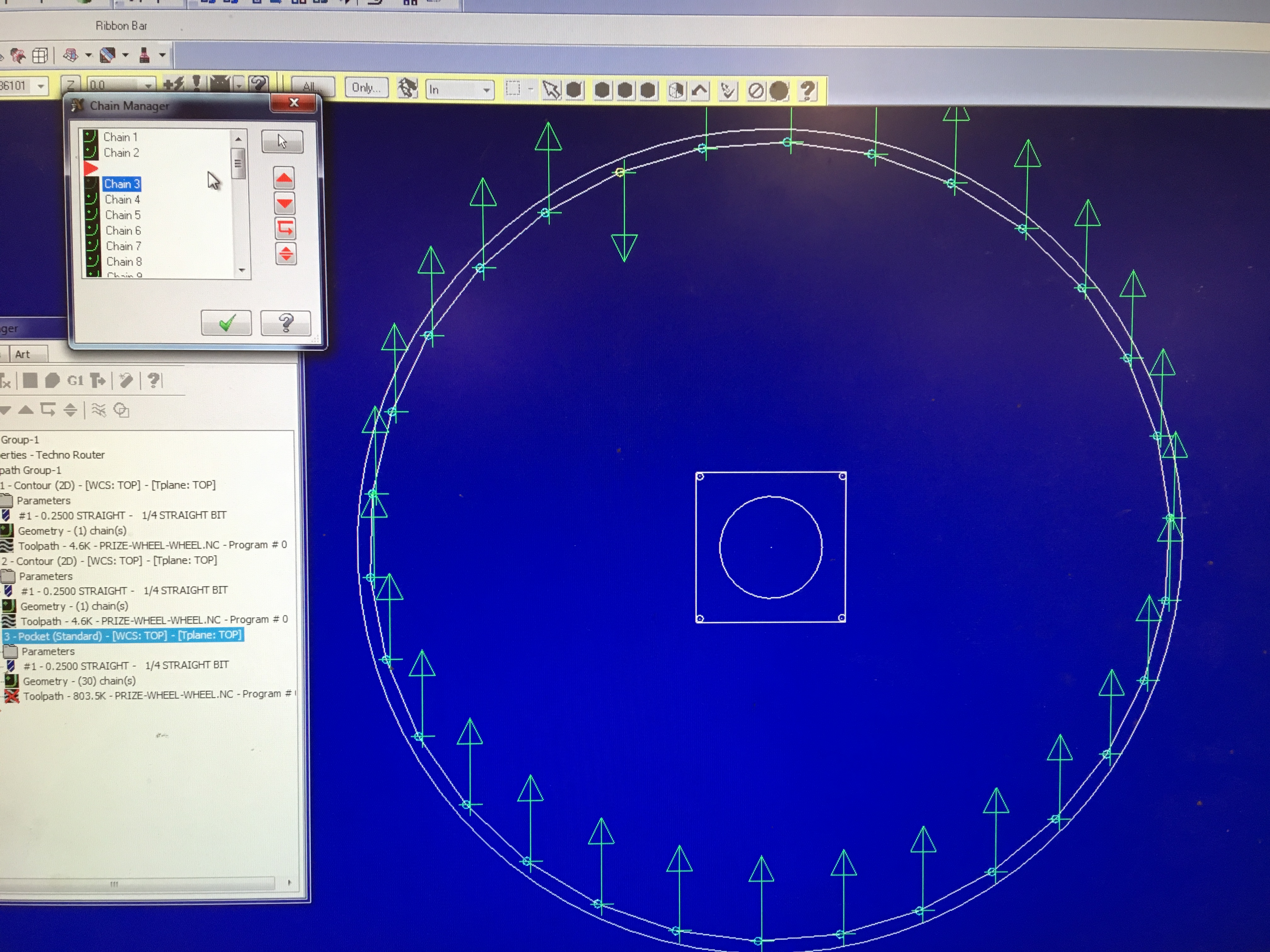

Falling in Love with MasterCAM

I’ve used MasterCAM before and while the UI is outdated I think it’s pretty great (and easy!) for what I’ve done so far.

Setting up pockets for the dowel pins. It was a pain to select and chain all the individual dowel pockets into one toolpath. And for some reason I don’t understand, I couldn’t change the direction of just that one stubborn dowel pocket at the top left. I ended up making a new toolpath for just that pocket.

Setting up pockets for the dowel pins. It was a pain to select and chain all the individual dowel pockets into one toolpath. And for some reason I don’t understand, I couldn’t change the direction of just that one stubborn dowel pocket at the top left. I ended up making a new toolpath for just that pocket.

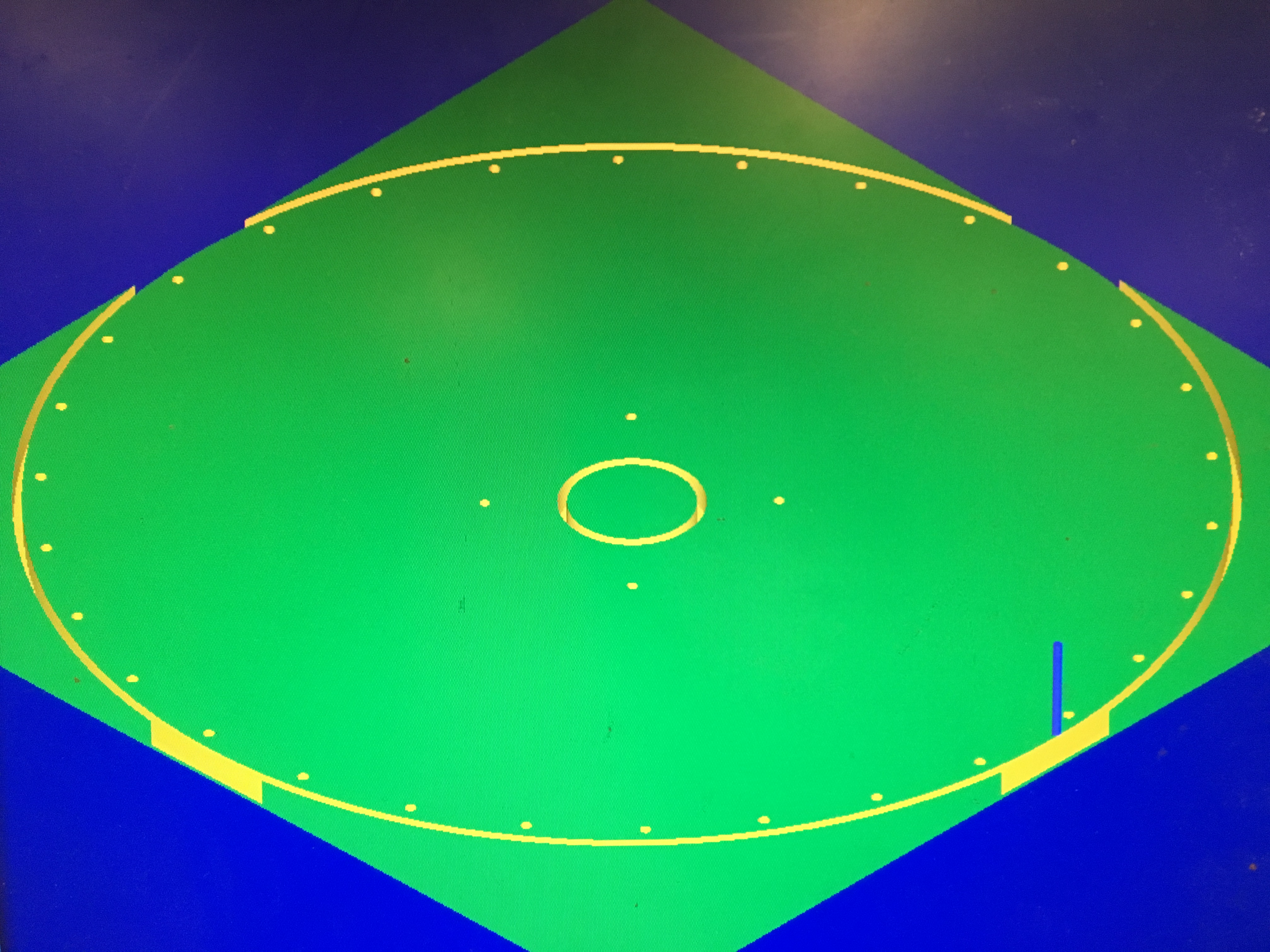

Sexy MasterCAM animation!

Sexy MasterCAM animation!

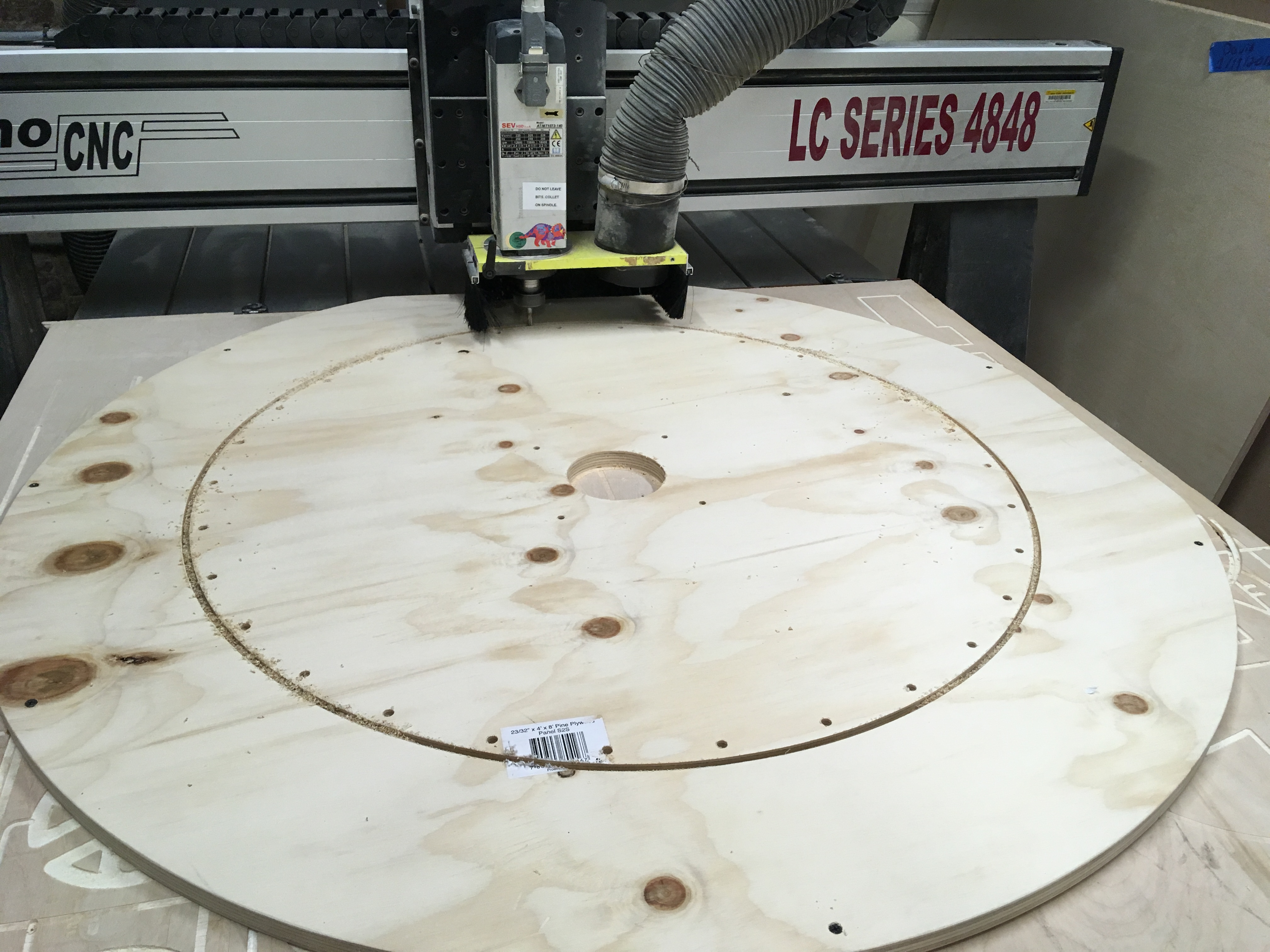

TechnoCNC is Magic

AHHHHH YEAHHHHHHHH!

My scrap is slightly bowed so I went wild with ~8 screws on all sides to keep it flatter against the spoilboard.

My scrap is slightly bowed so I went wild with ~8 screws on all sides to keep it flatter against the spoilboard.

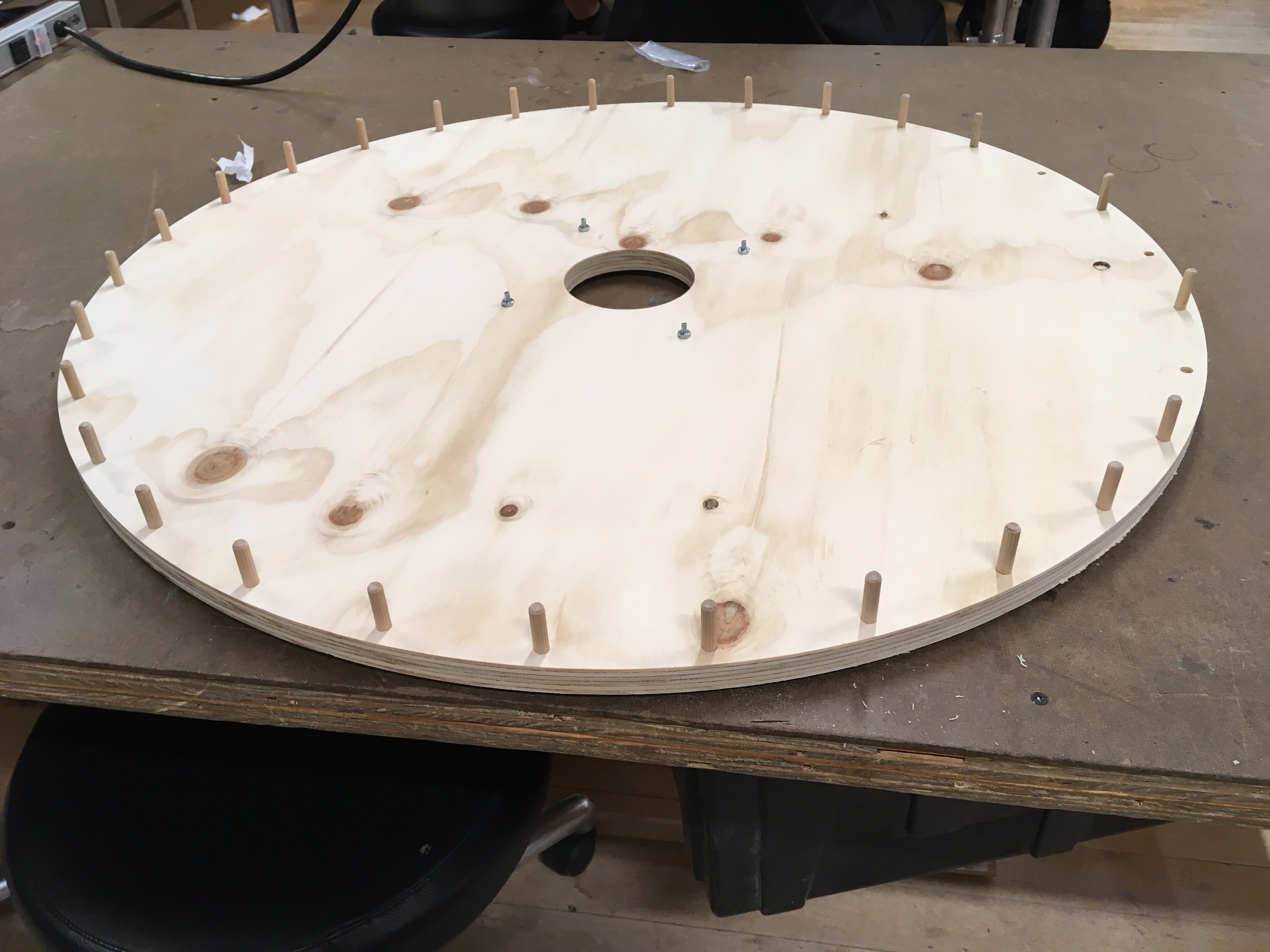

Because I wanted to try something new and my design is circular, I chose to put my origin in the middle of the wheel. I setup Vectorworks at the origin to account for this. This was nice because it also let me overcut the existing centerhole without too much measurement.

Because I wanted to try something new and my design is circular, I chose to put my origin in the middle of the wheel. I setup Vectorworks at the origin to account for this. This was nice because it also let me overcut the existing centerhole without too much measurement.

Here I cut a bigger hole around the small centerhole. Luckily, it doesn’t need to be precise so I eyeballed the origin.

Here I cut a bigger hole around the small centerhole. Luckily, it doesn’t need to be precise so I eyeballed the origin.

CNC pocketing the holes for dowel pins.

CNC pocketing the holes for dowel pins.

I cut the outer circle last since it creates a loose part.

I cut the outer circle last since it creates a loose part.

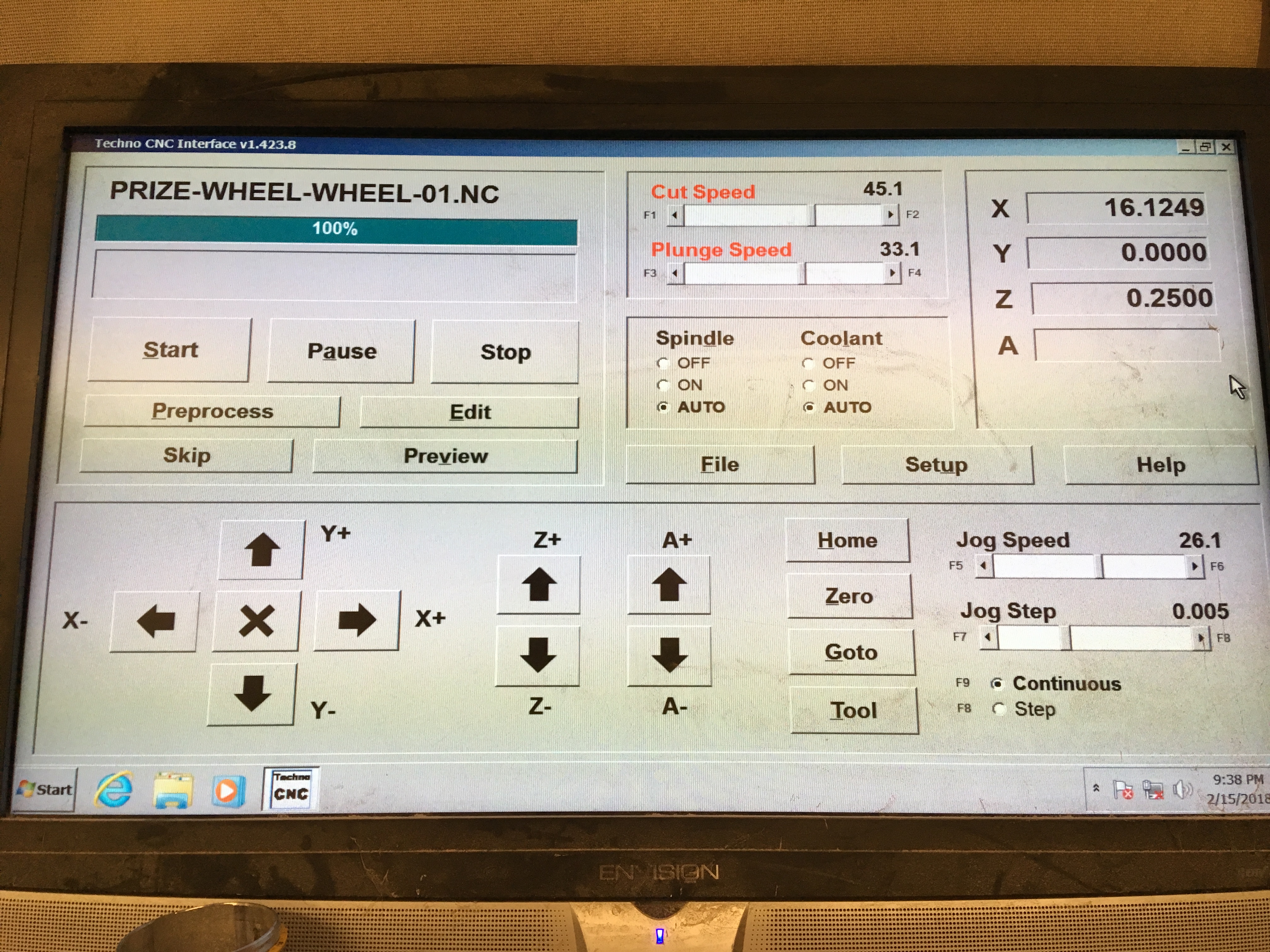

Beautifully simple TechnoCNC software with it’s on target time estimates and progress indicators. <3

Beautifully simple TechnoCNC software with it’s on target time estimates and progress indicators. <3

All cut out.

All cut out.

Mounting the lazy susan with some found screws. The screw holes work!

Mounting the lazy susan with some found screws. The screw holes work!

GENERIC…PRIZE…WHEEL! (WHEEL…OF…FORTUNE!)

Dowels are in, give it a spin!

It’s a bit wobblier than I hoped from the wood warp so rather than finish it with paint thinking I’ll re-do it with MDF next week.